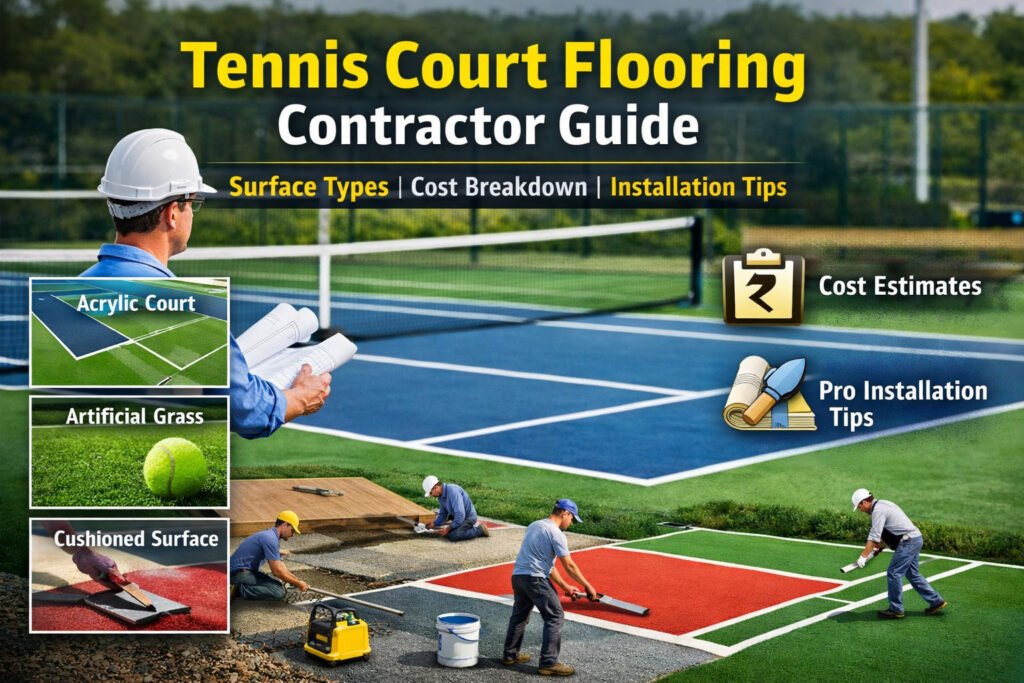

Tennis Court Flooring Contractor Guide – Surface Types, Cost & Installation Tips

Tennis court flooring isn’t just about looks—it’s the backbone of the entire playing experience. Think of it like the foundation of a house. You can have the most expensive rackets, professional-grade nets, and bright stadium lights, but if the surface beneath your feet isn’t right, everything else falls apart. Whether you’re building a private backyard court, a school facility, or a professional sports complex, choosing the right tennis court flooring can shape how the game is played, how safe players feel, and how long the court will actually last. The surface determines ball speed, bounce consistency, player movement, and even injury risk. A fast hard court encourages aggressive play, while a softer clay court slows the game and reduces stress on joints. On top of that, tennis court flooring directly impacts maintenance costs and long-term budgets. Some surfaces demand constant care, watering, and resurfacing, while others are almost “set it and forget it.” This is where a professional tennis court flooring contractors becomes essential. Flooring isn’t a DIY weekend project. It requires precise grading, drainage planning, material selection, and expert installation techniques. One small mistake during installation—like improper slope or poor base preparation—can lead to cracks, puddles, uneven bounce, and expensive repairs down the road. In this guide, we’ll walk through everything you need to know: different tennis court surface types, realistic cost expectations, and practical installation tips straight from the contractor’s playbook. Whether you’re a facility manager, property owner, or just exploring your options, this guide will help you make informed, confident decisions. Understanding the Role of a Tennis Court Flooring Contractor A tennis court flooring contractor does far more than just lay down a surface and walk away. They’re part engineer, part sports consultant, and part problem solver. Their role begins long before the first layer of material is installed and continues well after the court is finished. First, a contractor evaluates the site. This includes soil conditions, drainage patterns, slope, and available space. For outdoor courts especially, understanding how water moves across the land is critical. Poor drainage is one of the fastest ways to destroy a tennis court. A qualified contractor knows how to design a base that channels water away efficiently without affecting playability. Next comes material selection. Not all surfaces are suitable for every climate or usage pattern. A contractor helps match the right flooring system to your needs—whether that’s a low-maintenance acrylic hard court, a cushioned synthetic surface for player comfort, or a clay system for traditional play. They’ll also factor in budget constraints and long-term maintenance costs. During installation, precision is everything. Contractors manage base construction, leveling, surface application, line marking, and curing times. They use specialized equipment and follow strict tolerances to ensure consistent ball bounce and proper traction. After installation, many contractors offer maintenance plans, resurfacing services, and inspections to extend the court’s lifespan. In short, hiring an experienced tennis court flooring contractor isn’t an expense—it’s an investment in performance, safety, and durability. Key Factors to Consider Before Choosing Tennis Court Flooring Before selecting a tennis court surface, it’s important to step back and look at the bigger picture. The “best” surface doesn’t exist in isolation—it depends on how, where, and by whom the court will be used. Climate and Weather Conditions Weather plays a massive role in surface performance and longevity. In hot climates, surfaces must withstand UV exposure and extreme temperatures without cracking or fading. In rainy regions, drainage becomes a top priority. Freeze-thaw cycles in colder climates can wreak havoc on poorly designed bases, leading to cracks and uneven areas. Player Skill Level and Usage Frequency Is the court for casual recreational play, training beginners, or hosting competitive matches? Beginner-friendly courts often prioritize comfort and slower ball speeds, while advanced players may prefer faster, more responsive surfaces. High-traffic courts need durable materials that can handle constant play without excessive wear. Indoor vs Outdoor Courts Indoor courts have more flexibility in surface choice since they’re protected from weather. Outdoor courts, on the other hand, must be designed to handle environmental stressors. A contractor helps balance these factors to ensure optimal performance year-round. Taking time to assess these considerations upfront can save thousands of dollars in future repairs and resurfacing costs. Types of Tennis Court Surfaces Explained Tennis court surfaces generally fall into five main categories: hard courts, clay courts, grass courts, synthetic surfaces, and modular tile systems. Each surface has unique characteristics that influence gameplay, maintenance, and cost. Understanding these differences is crucial when working with a tennis court flooring contractor. The surface you choose will shape how the game feels, how much upkeep is required, and how long the court remains playable without major renovations. Below, we’ll break down each surface type in detail, highlighting what makes them unique and where they perform best. Hard Court Tennis Flooring Hard courts are the most common tennis surfaces worldwide, especially in public parks, schools, and professional tournaments. Typically constructed using asphalt or concrete bases with acrylic surface coatings, hard courts strike a balance between speed and control. One of the biggest advantages of hard court flooring is consistency. The ball bounce is predictable, which makes it ideal for training and competitive play. Players can rely on uniform response across the court, allowing skill—not surface quirks—to determine outcomes. From a contractor’s perspective, hard courts are durable and cost-effective. Once properly installed, they require relatively low maintenance compared to clay or grass. Occasional cleaning, crack repair, and resurfacing every 5–8 years can keep a hard court in excellent condition. However, hard courts are less forgiving on the body. The rigid surface can increase impact stress on knees, ankles, and hips. To address this, many modern installations include cushioned acrylic systems that add shock absorption without sacrificing performance. Hard courts work well in a wide range of climates, making them a versatile choice for both indoor and outdoor facilities. Clay Court Tennis Flooring Clay courts are known for their slower pace, higher bounce, and player-friendly characteristics. Traditionally made from crushed brick