When it comes to outdoor sports flooring in India, the weather isn’t just a background detail—it’s the main character. From scorching summers that can fry an egg on a metal surface to relentless monsoons that flood streets overnight, Indian climate conditions are intense, unpredictable, and often unforgiving. That’s exactly why Acrylic Flooring Is Better Than EPDM in such demanding environments. If you’re planning to build a tennis court, basketball court, skating rink, or multi-sport arena, the flooring choice you make isn’t just about appearance—it’s about survival.

Two of the most popular options in the Indian market today are Acrylic Flooring VS EPDM (Ethylene Propylene Diene Monomer) Flooring. At first glance, both look impressive. Both promise durability. Both are marketed as ideal for sports surfaces. But here’s the real question: which one truly performs better under Indian weather conditions?

Let’s think practically. In cities like Delhi, temperatures can cross 45°C in summer. In Mumbai or Chennai, humidity levels remain high almost all year. In Kerala and the Northeast, heavy rainfall is routine. Flooring that works perfectly in mild European climates may struggle in India’s aggressive environment.

Acrylic flooring has steadily gained popularity across India, especially in schools, sports complexes, and residential communities. Why? Because it adapts better. It handles UV rays more efficiently. It dries faster after rain. It maintains color and texture even after years of sun exposure.

EPDM, while useful in certain environments, often faces challenges under prolonged heat and heavy rainfall common in India.

In this article, we’ll break down every critical factor—heat resistance, monsoon durability, maintenance, cost, safety, and long-term performance. By the end, you’ll clearly understand why acrylic flooring consistently proves to be the smarter, more weather-resilient choice for Indian conditions.

Let’s dive deeper.

Table of contents

- Understanding Indian Weather Conditions

- What Is Acrylic Flooring?

- What Is EPDM Flooring?

- Durability and Lifespan in Indian Conditions

- Cost-Effectiveness Over Time

- Maintenance and Repair Simplicity

- Safety and Performance for Sports

- Environmental Suitability in Indian Cities

- Aesthetic Appeal and Customization

- Final Verdict: Why Acrylic Wins in Indian Weather

Understanding Indian Weather Conditions

India isn’t just one climate—it’s a collection of extremes. From desert-like heat in Rajasthan to coastal humidity in Goa, and from heavy monsoon zones in Kerala to cold winters in North India, flooring materials must endure a wide spectrum of environmental stress. Ignoring these realities can lead to costly repairs and premature surface failure.

Let’s break down the major weather challenges that outdoor flooring faces in India.

Extreme Heat and UV Exposure

Indian summers are not mild. They are intense, prolonged, and often brutal. In northern and central regions, surface temperatures can rise dramatically under direct sunlight. UV radiation levels are also significantly high for extended periods of the year.

Under such conditions, flooring materials can:

- Fade in color

- Become brittle

- Lose elasticity

- Develop surface cracks

Acrylic flooring is designed with UV-stable pigments and coatings that resist fading and degradation. EPDM, while somewhat UV resistant, can gradually harden or lose flexibility under consistent high temperatures.

Think of it like sunscreen. Acrylic has a stronger protective layer against the sun’s harsh rays.

Heavy Monsoon and Waterlogging

India’s monsoon season is beautiful—but merciless. Sudden heavy rainfall can flood courts within minutes. Poor drainage combined with absorbent materials can cause swelling, surface lifting, and mold growth.

Acrylic flooring is non-porous and dries quickly when properly installed over concrete or asphalt. EPDM surfaces, especially when used in certain installation formats, can trap moisture beneath layers, leading to long-term damage.

Humidity and Moisture Challenges

Coastal cities like Mumbai, Chennai, and Kolkata experience high humidity throughout the year. Moisture in the air continuously interacts with surface materials.

Materials that absorb or retain moisture tend to degrade faster. Acrylic coatings are designed to resist moisture penetration, making them more suitable for humid climates.

Dust, Pollution, and Temperature Fluctuations

Indian cities deal with heavy dust and pollution. Add to that the temperature shift between scorching days and cooler nights. These constant expansions and contractions stress flooring materials.

Acrylic systems are flexible enough to adapt to these micro-movements without cracking.

In short, Indian weather is demanding. Flooring must be heat-resistant, water-resistant, UV-stable, and durable under constant stress. As we move forward, you’ll see why acrylic flooring aligns more closely with these requirements.

What Is Acrylic Flooring?

Before comparing, it’s important to understand what acrylic flooring actually is and why it has become a preferred option for outdoor sports surfaces across India.

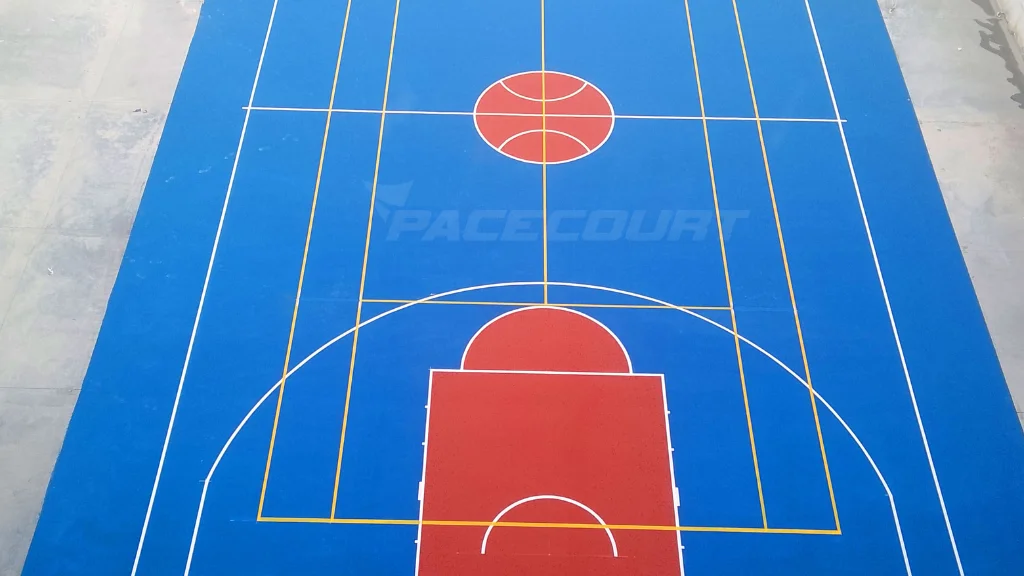

Acrylic flooring is a multi-layered synthetic surface system primarily used for sports courts. It is typically applied over a concrete or asphalt base and consists of several layers including primer, cushion (optional), base coat, and topcoat.

But what makes it special?

Composition and Material Structure

Acrylic flooring is made using acrylic resins combined with silica sand and specialized pigments. These components work together to create a surface that is:

- UV-resistant

- Slip-resistant

- Weather-resistant

- Flexible yet strong

Unlike rubber-based systems, acrylic coatings bond tightly with the base surface, forming a seamless and durable layer.

Common Applications in India

Across India, acrylic flooring is widely used in:

- Tennis courts

- Basketball courts

- Badminton courts

- School playgrounds

- Residential sports complexes

- Stadium practice areas

Its popularity comes from its balance of performance, durability, and cost-effectiveness.

Key Performance Features

Acrylic flooring stands out because it offers:

- Consistent ball bounce

- Quick drying after rain

- Strong UV stability

- Minimal color fading

- Low maintenance requirements

It’s like a reliable all-rounder in cricket—it may not always grab headlines, but it consistently performs under pressure.

Most importantly, acrylic systems can be customized with cushioned layers for added shock absorption. This makes them suitable for professional-level play while still being practical for schools and recreational areas.

As we move forward, we’ll compare this directly with EPDM to understand where the real differences lie.

What Is EPDM Flooring?

Before we continue the comparison, let’s clearly understand what EPDM flooring actually is. EPDM stands for Ethylene Propylene Diene Monomer—a type of synthetic rubber widely used in construction, playgrounds, and certain sports surfaces. At first glance, EPDM looks colorful, soft, and highly durable. It has a rubbery texture and is often associated with children’s play areas because of its shock-absorbing qualities.

But is it truly ideal for Indian outdoor weather? Let’s break it down carefully.

Composition and Material Structure

EPDM flooring is made from synthetic rubber granules mixed with a polyurethane binder. These granules are typically installed over a concrete or asphalt base, and sometimes over a shock pad layer. The rubber particles are bonded together to create a seamless surface.

The structure usually includes:

- Base layer (concrete or asphalt)

- Binder layer

- EPDM rubber granules layer

- Optional top sealing coat

The flexibility of rubber is what gives EPDM its cushioning effect. However, rubber-based materials behave differently under prolonged sun exposure and heavy rainfall compared to acrylic coatings.

Rubber expands when heated and contracts when cooled. In India, where daytime and nighttime temperature differences can be drastic, this constant expansion and contraction can create stress within the material. Over time, this may lead to surface separation or minor cracks.

Where EPDM Is Commonly Used

In India, EPDM is more commonly found in:

- Children’s playgrounds

- Jogging tracks

- Landscaping areas

- Certain multi-purpose courts

- Recreational walking paths

It is less commonly used for professional-level tennis or basketball courts compared to acrylic flooring. Why? Because EPDM, while soft and shock-absorbent, may not provide the same level of ball bounce consistency required for competitive sports.

General Advantages and Limitations

EPDM does have some strengths:

- Excellent shock absorption

- Soft underfoot

- Available in multiple vibrant colors

- Good slip resistance

However, its limitations become visible in harsh climates:

- Surface can heat up significantly under direct sunlight

- Colors may fade faster in intense UV conditions

- Water can seep between granules if installation is not perfect

- Repairs can be complicated and visually mismatched

Think of EPDM like a comfortable cushion—it feels great initially, but under extreme stress, it may not hold its form as well as a rigid yet flexible acrylic system.

Now that we understand both materials, let’s directly compare their performance under India’s most challenging weather elements.

Heat Resistance: Acrylic vs EPDM

Let’s be honest—Indian summers are ruthless. In cities like Nagpur, Jaipur, or Delhi, outdoor surfaces can become so hot that walking barefoot is impossible. So the big question is: which flooring handles extreme heat better?

Performance Under Direct Sunlight

Acrylic flooring is specifically engineered for outdoor exposure. It contains UV-stable pigments that resist fading and structural breakdown. Even after years of exposure to intense sunlight, the surface remains intact and stable.

EPDM, being rubber-based, reacts differently. Rubber tends to absorb heat. Under prolonged exposure, EPDM surfaces can become excessively hot. Over time, continuous heating and cooling cycles may reduce flexibility and lead to surface hardening.

Imagine leaving a rubber mat outside in peak summer—it becomes softer and sometimes sticky. Now multiply that effect across an entire sports court.

Surface Temperature Comparison

While both surfaces heat up, acrylic courts typically cool down faster once sunlight reduces. EPDM’s rubber composition can retain heat for longer periods.

This has real-world implications:

- Players feel more surface heat during afternoon games

- Increased discomfort in barefoot sports

- Potential reduction in playtime during peak summer

In Indian conditions where afternoon temperatures remain high until evening, quicker cooling becomes a major advantage.

Long-Term Impact of UV Rays

UV radiation slowly breaks down materials at a chemical level. Acrylic coatings are designed with UV resistance built into the formulation. That’s why you often see acrylic tennis courts maintaining their color for many years.

EPDM granules, especially lighter shades, may fade or discolor more noticeably over time. In high-UV regions, this difference becomes very apparent after just a few years.

In short, when it comes to battling Indian heat and UV intensity, acrylic flooring stands stronger, longer, and more stable.

Monsoon Performance Comparison

If summer tests heat resistance, monsoon tests survival. Heavy rain, water stagnation, and high humidity expose the true quality of any outdoor flooring.

Water Resistance and Drainage

Acrylic flooring systems are non-porous when properly installed. Water stays on the surface and drains away efficiently if the base slope is correct. Once rain stops, the surface dries relatively quickly.

EPDM surfaces, due to their granule structure, may allow water to seep between particles. If the binding layer is compromised even slightly, moisture can penetrate below the surface. Over time, this can weaken the bond between layers.

In regions like Kerala or Assam where rainfall is frequent and heavy, quick drying and strong surface bonding are critical.

Slipperiness and Player Safety

Wet surfaces can become dangerous. Acrylic courts are designed with textured silica sand in the top layer, providing grip even when slightly damp.

EPDM surfaces generally offer good traction, but prolonged moisture exposure may reduce surface firmness. In some cases, algae growth can occur if water remains trapped in porous sections.

Risk of Peeling or Surface Damage

Improperly maintained EPDM surfaces may show signs of peeling or bubbling after repeated water exposure. Acrylic systems, because they chemically bond with the base, are less prone to such issues.

Think of acrylic like a waterproof paint that seals the surface. EPDM behaves more like a layer placed on top—if water finds its way in, problems can develop underneath.

When monsoon season lasts for months, durability against moisture becomes non-negotiable. Acrylic clearly holds the edge here.

Durability and Lifespan in Indian Conditions

Durability isn’t just about surviving one summer or one monsoon—it’s about performing year after year without major repairs.

Wear and Tear Resistance

Acrylic flooring offers excellent abrasion resistance. It handles:

- Continuous foot traffic

- Sports shoe friction

- Ball impact

- Regular cleaning

EPDM, being softer, may show surface wear faster in high-traffic sports areas.

Crack and Fade Resistance

Acrylic systems are flexible enough to handle minor substrate movements without cracking. High-quality systems maintain color vibrancy for years.

EPDM may experience granule loss over time, especially in areas of intense use.

Maintenance Requirements

Acrylic flooring requires:

- Periodic cleaning

- Occasional recoating after several years

EPDM may require:

- Granule patch repairs

- Binder reinforcement

- More complex resurfacing

Over a 7–10 year span, acrylic typically demands less intensive intervention.

Durability in India means resisting heat, rain, dust, pollution, and heavy use. Acrylic consistently proves to be the more stable and long-lasting option.

Cost-Effectiveness Over Time

When choosing between acrylic flooring and EPDM, cost is often the first thing people look at. But here’s the truth—initial price and long-term value are two very different things. In Indian weather conditions, where climate stress is constant, the real cost of flooring isn’t just installation. It’s maintenance, repairs, downtime, and lifespan.

Let’s break it down practically.

Initial Installation Cost

At first glance, EPDM flooring may appear slightly more affordable in certain installations, especially for playground applications. However, when we talk about sports courts—tennis, basketball, multi-purpose grounds—acrylic flooring offers competitive pricing with structured layering systems.

Acrylic systems are typically installed over concrete or asphalt bases using multiple coating layers. The process is systematic and standardized, which helps maintain predictable costs.

EPDM installation requires:

- Rubber granules

- Polyurethane binders

- Skilled labor for mixing and laying

- Careful curing

If the installation is not done properly, issues may arise sooner than expected. That means additional costs later.

Maintenance Cost Comparison

Here’s where acrylic starts pulling ahead.

Acrylic flooring requires:

- Basic cleaning

- Occasional surface recoating after several years

- Minimal structural repairs

EPDM surfaces, especially in Indian heat and monsoon cycles, may need:

- Patch repairs

- Granule refilling

- Binder touch-ups

- Surface leveling corrections

Small repairs in EPDM can sometimes look uneven due to color variation between old and new granules. That often means replacing larger sections just to maintain visual consistency.

Long-Term ROI (Return on Investment)

Let’s think long-term—10 years.

Acrylic courts typically maintain performance with limited intervention. Even after years of exposure, resurfacing is relatively simple and cost-effective.

EPDM may require more frequent spot repairs in high-use areas. Over time, these maintenance cycles add up.

If you compare:

| Factor | Acrylic Flooring | EPDM Flooring |

|---|---|---|

| Initial Cost | Moderate | Moderate |

| Maintenance | Low | Moderate to High |

| Lifespan | 8–12+ Years | 6–10 Years |

| Repair Complexity | Simple | Moderate |

In Indian conditions, acrylic flooring delivers better long-term value because it handles environmental stress more efficiently. Less stress means fewer repairs. Fewer repairs mean lower total cost.

And that’s what smart investment really looks like.

Maintenance and Repair Simplicity

Let’s be honest—no one wants a flooring system that becomes a headache. Maintenance should be simple, predictable, and affordable. In India, where dust, pollution, rain, and heavy usage are daily realities, easy upkeep is not optional—it’s essential.

Cleaning and Upkeep

Acrylic flooring is relatively easy to clean. Most of the time, regular sweeping and occasional washing with water is enough. Because the surface is seamless and non-porous, dust and dirt don’t get trapped easily.

In high-pollution cities like Delhi or Mumbai, this becomes a major advantage. A quick wash restores the surface appearance and grip.

EPDM surfaces, due to their granule texture, may trap dust and debris between particles. Over time, this can:

- Affect appearance

- Encourage algae growth in humid areas

- Make cleaning slightly more labor-intensive

Repair Process Differences

If acrylic flooring develops minor wear, the repair process is straightforward:

- Clean the affected area

- Apply fresh acrylic coating

- Allow it to cure

The repaired section blends well with the existing surface.

EPDM repairs can be more noticeable. Matching old and new granules perfectly is challenging. Even slight color variation becomes visible under sunlight.

Availability of Skilled Labor in India

Acrylic flooring systems are widely installed across India. Many contractors specialize in this system, making labor availability easier and more competitive.

EPDM installation and repair require specific expertise in rubber granule mixing and polyurethane binding. Not every contractor handles it efficiently.

In practical terms, acrylic flooring offers smoother maintenance management. Less complexity means fewer operational disruptions.

Safety and Performance for Sports

Flooring is not just about surviving weather—it’s about delivering performance. Especially in sports environments, surface quality directly affects player safety, comfort, and game experience.

Shock Absorption

EPDM is naturally soft due to its rubber composition. That makes it excellent for playgrounds where children may fall.

However, modern acrylic flooring systems can include cushioned layers. These systems offer controlled shock absorption without compromising firmness required for competitive sports.

The key difference? Acrylic provides balanced cushioning, while EPDM can sometimes feel too soft for professional ball games.

Ball Bounce Consistency

This is critical.

Acrylic flooring delivers consistent and predictable ball bounce. That’s why most professional tennis and basketball courts in India use acrylic systems.

EPDM’s softer surface may absorb more energy from the ball, resulting in slightly inconsistent bounce patterns—especially as the surface ages.

For competitive sports, predictability matters. Players rely on uniform surface response.

Surface Grip and Player Comfort

Acrylic courts are designed with textured top layers that provide excellent grip. Even during quick turns and sudden stops, athletes feel stable.

EPDM surfaces also offer good traction but may slightly change in firmness depending on temperature.

Imagine playing on a surface that feels different at noon compared to evening—that inconsistency can impact performance.

When sports quality is the priority, acrylic flooring stands out as the more reliable choice.

Environmental Suitability in Indian Cities

Performance in Coastal Areas

India’s geography is diverse. What works in Jaipur may not work in Kochi. Let’s examine how both flooring types perform across different regions.

Coastal cities face:

- High humidity

- Salt-laden air

- Frequent rainfall

Acrylic flooring resists moisture penetration and surface degradation. Properly sealed systems handle humidity well.

EPDM may experience gradual binder weakening if exposed to prolonged moisture and salt exposure.

Performance in Northern Hot Regions

North India experiences extreme summers and cold winters. Acrylic systems adapt well to temperature swings due to flexible resin properties.

Rubber-based EPDM can harden slightly in colder temperatures and soften in extreme heat.

Performance in High Rainfall Zones

In areas with heavy monsoon patterns, quick drainage and water resistance are critical.

Acrylic surfaces dry faster and are less prone to moisture trapping.

Across varied Indian climates, acrylic flooring demonstrates more consistent adaptability.

Aesthetic Appeal and Customization

Let’s not ignore the visual aspect. Sports courts and playgrounds should look vibrant and professional.

Color Retention in Sunlight

Acrylic flooring contains UV-resistant pigments designed to maintain color vibrancy even under strong Indian sunlight.

EPDM colors may fade over time, particularly lighter shades.

Surface Finish Options

Acrylic courts offer:

- Matte finishes

- Textured surfaces

- Multiple color combinations

- Professional line markings

EPDM surfaces are colorful but may lack the same crisp finish for sports markings.

Branding and Court Markings

Acrylic systems allow precise court line painting that remains visible for years.

For schools, academies, and sports complexes, professional appearance matters.

Final Verdict: Why Acrylic Wins in Indian Weather

When you evaluate everything—heat resistance, monsoon durability, maintenance simplicity, sports performance, cost efficiency, and adaptability across Indian regions—the pattern becomes clear.

Acrylic flooring is engineered for outdoor resilience. It handles extreme heat without breaking down. It resists heavy rainfall without trapping moisture. It maintains color despite intense UV exposure. It provides consistent sports performance year after year.

EPDM has its place, especially in playgrounds and cushioned recreational areas. But when it comes to outdoor sports courts exposed to India’s challenging climate, acrylic flooring consistently delivers stronger long-term performance.

It’s not about which material is “good” or “bad.” It’s about which one is better suited for Indian weather conditions.

And the answer, again and again, is acrylic.