Why Synthetic Badminton Court is Better than a Wooden Court?

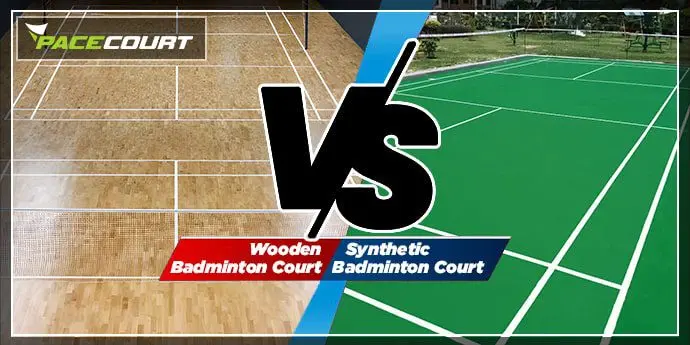

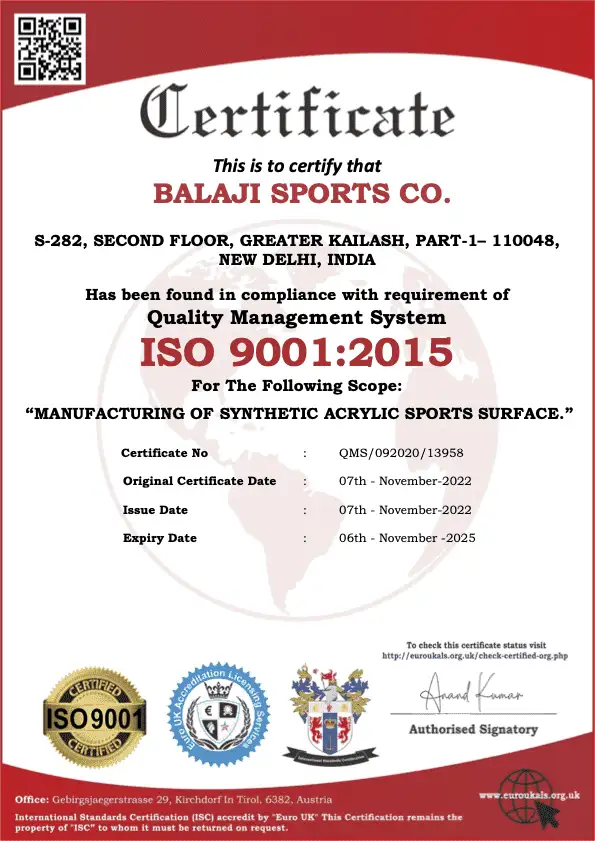

Introduction: When it comes to badminton, choosing the right playing surface can mean the difference between a great game and an infuriating one. Although wooden courts have always been associated with the sport, synthetic acrylic courts have revolutionized our perception and experience of badminton. Pacecourt is one of the leading producers of synthetic acrylic sports flooring materials which perform better than traditional wooden courts in numerous ways. This blog examines why a Synthetic Badminton Court is Better than a Wooden Court for players, venue owners, and event organizers. Discover how Pacecourt’s synthetic courts are changing the parameters for quality in badminton from reliability and uniformity to versatility and safety. Comparing Wooden and Synthetic Court: It can be realized that when it comes to selecting the perfect badminton playing surface. Synthetic Badminton Court is Better than a Wooden Court as they are way too different from each other in various ways. Resilience: However old-fashioned wooden courts tend to deteriorate with time. Exposure to moisture, insects, and general use causes it to warp, splinter, and degrade. Conversely, synthetic courts made of durable acrylic materials exhibit unmatched resilience. These courts resist heavy-duty usage and wear out thereby continuing to perform well for an extended period. Hence offering a long-term investment possibility. Steadiness: Inconsistent variations on the quality of the court’s surface like those influenced by weather conditions. The aging process as well as care-taking practices are major problems in wood courts. Such disparities could affect ball bounce and player movements thereby affecting fairness during games. On the contrary, artificial surfaces do not get affected by these externalities hence remaining smooth throughout. Synthetic materials provide an even bounce pattern and grip facilitating competition among equals thus improving game experiences in totality. Versatility: Wooden courts are not just very customizable in terms of how they look and what their functions are. This is why synthetic courts offer the greatest flexibility. The facility owners have a wide range of colors, designs, and textures for the surface to be able to customize it to fit their preferences or branding requirements. Moreover, synthetic courts can be installed inside or outside easily allowing them to choose venues flexibly and adapt to different settings. Maintenance: However, maintaining wooden courts necessitates a lot of work and expenses. Regular sanding, refinishing, and repair work are mandatory for keeping the surface in its best condition. Conversely, synthetic courts require minimal upkeep. Routine cleaning and occasional checks on the surfaces will suffice for their performance to stay intact as well as for them to remain looking new thus saving time and resources for those who own them. Player Safety: In any game, safety comes first which has been given prominence by synthetic courts. As opposed to wood that may cause injuries due to splintering surfaces that may be uneven; this is unsafe for players in such kind of court type. However, slip resistance levels are very high with excellent shock absorption features built into artificial fields, unlike other court types like wooden ones which have neither of these qualities nor many others including splintering floors or uneven grounds. Cushioning systems integrated with synthetic courts enhance players’ comfort during playtime making it less risky since people will get injured less often than they do playing under other conditions provided by wooden floors when they enjoy lighter moments at times which are safer too. Why Choose Pacecourt? Reasons to choose Pacecourt for your synthetic acrylic sports flooring: Innovative Technology: Pacecourt uses cutting-edge technology and the newest materials to make synthetic courts that go beyond industry standards. Pushing the boundaries of what is possible in sports flooring, Pacecourt focuses on innovation and excellence. Customization Options: The possibility to customize your court’s aesthetics by Pacecourt is endless. When it comes to colors, designs, or surface textures, for instance; you need a Pacecourt court that will reflect your unique style as well as branding. Unrivaled Durability: Pacecourt’s synthetic materials are engineered to be as durable as possible so that your court can survive the constant usage lifetime and still look new even for a long time. Consistent Performance: If you choose to buy a court from Pacecourt, you are guaranteed to have even play surfaces every day you want to play. That means no chances of unfairness or uneven bounces when playing games—there should always be level ground for all levels of players on Pacecourts courts. Exceptional Safety Features: Safety is very important in sports hence the reason why every aspect of pacecourts design is aimed at making our players safe. Shock absorption greatness along with non-slip surfaces are some examples of this emphasis on player safety. Experts in the Industry: Pacecourt is an unrivaled company with vast knowledge of sports flooring as a result of being active for many years. Whatever you are to do with your court, either put up a new one or refurbish the old one. Pacecourt’s team of specialists is ready and devoted to giving results that exceed your expectations. Customer Satisfaction: The main priority at Pacecourt is customer satisfaction. We offer personal service and support throughout this process, from first consultation through installation and beyond. We only succeed when you have succeeded. Conclusion: In this blog Why Synthetic Badminton Court is Better than a Wooden Court. Among the synthetic badminton courts that have flooded the market. Pacecourt is the preferred choice for serious players, facility owners, and event organizers. Innovation, Customization, durability, performance/sporting attributes, and safety measures. These are the main features of what they provide to those who seek their services. Whereas Expertise and Customer satisfaction sum up other aspects that make them a leading firm in this field. By selecting Pacecourt for your synthetic badminton court floor requirements you are not just buying a court. But getting involved with partners whose aim is to make sure that your gaming experience is taken to another level. This day discover the difference between Pacecourt and others on value, reliance, and success like never before!