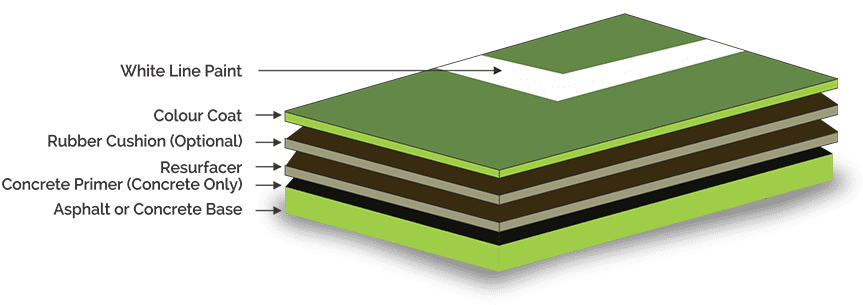

Acrylic Resurfacer is the second step in building a court; the first step is to apply Primer. Pacecourt Resurfacer is an essential product to use; let us now discuss how Acrylic resurfacer can benefit the court.

Every court needs to be sufficiently smooth and free of uneven pavement. To put it simply, primer fills in small gaps while resurfacer levels the surface properly. For instance, if the base has both small and large holes, the primer will fill in the smaller ones while the resurfacer will fill in the larger ones and level the base, One question arises: why use a primer if the resurfacer fills the gaps and levels the surface? Read this blog to learn more about why pacecourt primer is important in concrete.

Pacecourt Acrylic Resurfacer, which is 100% acrylic-based and contains a selection of fillers and fibers that smooths the surface. The resurfacer is blended with two ingredients: silica sand and cement. When coupled with silica sand, resurfacer is designed as an acrylic filler; when combined with cement, it is designed as an acrylic fiber coat, and perhaps most importantly, there is no lead, mercury, or asbestos in acrylic resurfacer. Lead, mercury, and asbestos are all harmful chemicals that can be used to increase the beauty of a court but are bad for it over the long term. However, pacecourt manufactures products that can still enhance a court's aesthetic without using these harmful chemicals, which explains why a court made of pacecourt materials is durable.

Surface Preparation

After the base is ready, the next step will be to apply pacecourt acrylic concrete primer as previously discussed. Using a primer is very important due to the bond between the surface and the court, and the surface must be clean, free of all dirt and dust, as well as other things like pins, nails, stones, etc., and must be dry before applying. The surface takes 30 days to dry. Before applying any coating, the entire surface must be saturated with water to check for any depressions that are 1/16" or larger. Applying a pacecourt deep patch for undulation is the initial step if a surface depression of 10-15mm has been discovered. For more information on deep patch, visit this blog. If the surface depression is between 3 and 4mm, the same method will be used to apply primer first, then resurfacer.

Acrylic resurfacer can also be used to fill small depressions (⅛” or less) by combining 1 part of Acrylic Resurfacer with Pacecourt silica sand. If necessary, add a small amount of water to achieve workability.

Installation

Once the patching is finished, the surface will receive 1-2 applications of pacecourt acrylic resurfacer. After adding water and silica sand, the acrylic resurfacer must be thoroughly mixed until the material is consistent. The amount and size of the sand can be adjusted to achieve different textures and filling properties. Larger sand will have better filling properties. A soft, rubber squeegee should be used to apply the mixed product to the surface. The finished surface must be uniform in appearance and free of ridges and tool marks. If more than one application is used, the second application should be at a 90° angle to the first application. Depending on the weather, acrylic resurfacer takes 6 to 12 hours to dry.

Mixture

50KG of Pacecourt Acrylic Resurfacer

40KG Cement

50KG of Pacecourt Silica Sand

Clean drinking water @ 1.10 KG/Sqm.

Coverage

Pacecourt Acrylic Resurfacer coverage is approximately 0.29 - 0.40 KG/m2 per undiluted application. Depending on the porosity or texture of the pavement, coverage may vary.

In the end

Since pacecourt is a well-known brand for sports flooring, you won't find the same quality material anywhere else. If you need samples or have other questions, contact us and one of our experts will be happy to help you.